Flat Sawn-Quarter Sawn:

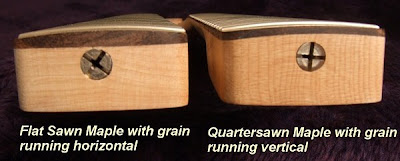

There are many questions that come up when discussing the differences between these two woods and hopefully we can try to answer some of those questions here and explain some of the differences as well. Shown here in this photo is a Flat Sawn neck with a standard fingerboard on the left and a Quarter sawn neck with a vintage veneer contoured fingerboard on the right. As you can see from the picture, the grain lines on the flat sawn neck are running left to right and the grain lines on the quarter sawn neck are running up and down. Quarter sawn and flat sawn woods are cut with a different grain orientation and come from different areas of the tree. This greatly affects the internal strength of both and subsequently, the quarter sawn neck tends to be a tighter grain and allot stronger and more stable than the flat sawn.

The quarter sawn wood is usually very straight and rigid and the flat sawn is much more pliable. There are advantages to both types of woods. Due to its strength and stability, the quarter sawn is a great wood for use with heavier string gauges, unfinished necks, necks with a stronger dual acting truss rod, and longer necks like bass necks etc. There is also a difference in tone on these woods. The quarter sawn has a distinctly brighter tone due to its density.

The Flat sawn neck tends to have a more mellow tone and is more pliable so it is better for use with vintage style, single acting truss rods and does very well with a hard finish but can also be left unfinished as well. Aesthetically speaking, the wood grain is much more visible on a flat sawn neck as opposed to a quarter sawn neck. Flamey and Birdseye necks are most often flat sawn.

--------------------------------

There are a variety of ways that lumber can be cut out of a log. These include plainsawing, riftsawing and quartersawing. Each method has its own advantages and disadvantages. Quartersawn wood is created by cutting a log lengthwise into quarters, then creating a series of parallel cuts, with the middle cut being perpendicular to the tree's rings.

The grain patterns of wooden boards can affect the way that they expand and contract. In quartersawn wood, the grain patterns are relatively consistent, so the end product is stable, which makes it preferred by many woodworkers and furniture-makers. Quartersawn wood might include medullary rays and wavy grain patterns that some people prefer over the patterns that are revealed through the other sawing methods. Oak is the most common quartersawn wood, although builders might also be able to find quartersawn walnut, cherry and maple.

Quartersawn wood's stability makes it highly sought after for making musical instrument parts such as string instrument necks and fret boards. In most cases, it is best for a wooden part of a musical instrument, such as the neck of guitar, bass or violin, to remain stable throughout the instrument's life. Using quartersawn wood helps ensure that the instrument's sound will remain as invariable as possible.

One disadvantage of quartersawing wood is that it leaves some scrap. This typically makes quartersawn wood more expensive than plainsawn wood, because plainsawing produces little to no scrap. Quartersawing's yield, however, is greater than in riftsawing, so quartersawn wood typically is cheaper than riftsawn wood.

Plainsawing is perhaps the most straightforward way to cut rectangular-profiled boards out of a round log. Sawmills create plainsawn lumber by cutting a log lengthwise with a series of parallel cuts. This system provides excellent yield because it minimizes scrap, but plainsawn lumber has some disadvantages. Depending on where they were cut out of the log, plainsawn boards can have substantially different grain patterns, which can cause it to expand and contract in different ways. Plainsawn wood, however, often has interesting grain patterns, sometimes called cathedrals, that are not created by other types of cutting.

Riftsawn lumber is much more stable than plainsawn lumber. Each board is cut perpendicular to the log's rings, so each board has essentially the same grain pattern. Furniture made of riftsawn wood has more of a uniform appearance because of the similarity of grain patterns in the boards. Rift-sawing provides very poor yield, however, leaving lots of wedge-shaped scraps. Its low yield is why riftsawn wood is rarely produced by lumber yards, which typically makes it more expensive than quartersawn or plainsawn wood.

Niciun comentariu:

Trimiteți un comentariu